August 16, 2023

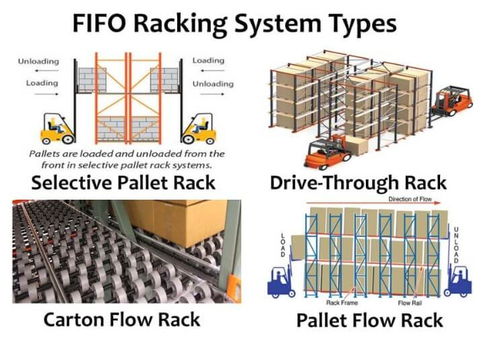

First-in, first-out (FIFO) is an inventory management process that allows inventory placed in the rack system to be removed first. The first-in-out-rack system is ideal for customers who require rapid inventory turnover, high inventory turnover, or store goods with expiration dates. For example, first-first-out food storage applications allow continuous product movement, ensuring no inventory deterioration or waste. With a variety of different first-in-out rack systems, you will definitely find a first-in-out rack option suitable for your warehouse or distribution center.

![]()

Selective tray rack

Selective packing allows direct access to all stored pallets or cartons without moving other pallets or cartons, making it a highly selective solution. A large number of channels are required to accommodate this high selectivity. This is a less dense option compared to other types of rack systems. Selective pallet racks are ideal for warehouses where continuous products circulate or require simultaneous access to all pallet goods. Selective pallet holders are a good choice for first-in, first-out food storage management.

![]()

![]()

Drive-thru/in rack

The rack is designed to store pallets on support rails that are attached to uprights and are fed into the system by a forklift that lifts the load to the height of the rails and places it in the selected storage location. This provides high storage density by eliminating pick lanes, but low selectivity. Drive-through racks are ideal for storing large quantities of similar products, long-life products, and products that only require a lot of one-time moving.

![]()

![]()

Gravity flow system

This includes both the carton flow and the tray flow. They are designed to rack and support sloping rollers or wheels. This allows the product to slide from the rear loading channel to the front picking channel. Gravity frames provide excellent roll utilization. Gravity flow can be configured in many different ways. Such as independent systems integrated with various tray rack types, or within multilevel picking modules. Gravity flow systems are ideal for storing materials with a shelf life such as food and beverages, materials of different sizes, and frozen or refrigerated applications. Carton flow frames are also ideal for bulk box-picking and piece-picking applications.

![]()

![]()

Carton flow rack

A racking system called case flow, often referred to as carton flow, uses a conveyor that is slightly inclined to enable cases to move freely over a sloped plane. Gravity-driven cases and carton flow racking systems usually have motion and braking devices to regulate the pace of the moving goods. Case and carton flow systems, which work similarly to conveyor rack systems and can pick from the front case while maintaining reserve storage in the rear cases, as well as offering wide rollers and full bed skate wheels to maximize productivity, increase productivity and free up space. Carton Live Storage Provides stock rotation on a strictly "First In" & "First Out" Principle.

![]()

![]()

First-in, first-out racks are good for many types of operations. Some common advantages include:

First-in, first-out shelf systems can be combined with other types of material handling solutions such as pallet shelves, and semi-automatic, or fully automated systems. Customizing your product and throughput requirements in this way will maximize your available storage space and increase efficiency.

Ironstone product customization services

Ironstone-Meca Industry has great knowledge and experience in the design, engineering, and installation of FIFO rack systems. As a system integrator, we will work with you to provide a turnkey system. From engineering, design, product procurement, subcontractor management, installation, and licensing support, IRONSTONE handles everything for you. We have a team of excellent in-house project managers and engineers with extensive experience in the material processing industry. We will work with you to ensure that your system is best for your operations and installed and completed on time within budget. For more information or quotes, we hope to have the opportunity to help you further.